The Edwards range of instruments offers:

- Measurement over the range 2000 to 10-11 mbar

- Advanced microprocessor based controllers

- Calibration of instruments to UK national standards

Selecting Your Vacuum Gauge

Edwards offers a wide choice of vacuum measurement and control products – from dial gauges to microprocessor based gauge controllers. Within each product range, there is a family of models designed to meet the widest user specification.

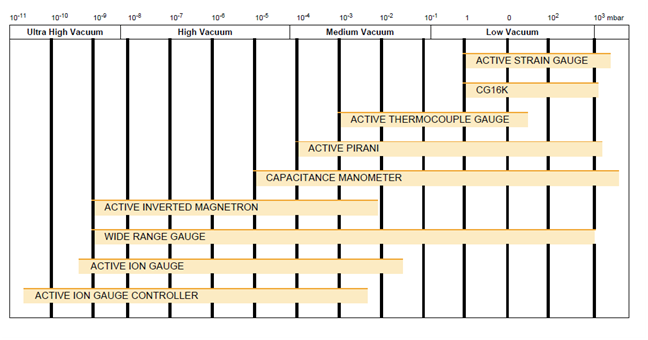

The first step in selecting the right gauge to meet your application isto decide the range of pressures that you want to measure at each of your measuring points. The chart below indicates the broad pressure ranges covered by the spectrum of Edwards instruments: use this chart as a primary guide to the choice of gauge head.

The second step is to establish your requirement for the output of the pressure measurement. If you simply want an indication that a certain level of vacuum has been reached (for example, to open a valve orstart a process), then a vacuum switch or Active gauge head alone-may be appropriate. If you want to display the pressure locally, then a dial gauge may be suitable. If you need the pressure display to be-remote from the measurement point (for example, in a control panel)then select the TIC Instrument Controller or Active Digital Controller,depending on the features you require. (You will also need to select appropriate gauge head(s) to accompany these displays and controllers.) If your control system (such as a PLC, PC or dedicated microprocessor controller) needs to know the pressure to make sequence decisions but you do not need a separate vacuum display,then you can use an Active gauge head as a stand-alone transducer connected to an appropriate power supply and control system analog input.

Thirdly, you need to select a gauge suitable for the process gases and constructed to withstand exposure to the external environment ofyour vacuum system. Consider both whether the gauge will survive inthe process and also whether the process gases will affect thegauge’s measurement. For example, the measurement made bymechanical gauges (vacuum switches, dial gauges, strain gauge sand capacitance manometers) is not affected by gas composition,whereas that made by other

types of gauges is gas dependent.

Calibration for Different Gases

All of our gauge heads are calibrated for dry nitrogen; the calibrationfor dry

air is the same. If you use thermal conductivity or ionizationgauges with gases other than nitrogen or air, you may need to applya gas correction factor for an accurate indication of your systempressure. Please contact us if you need more information.